Adlan-Vot Tech Services

A Steel & Metal Fabrication Company.

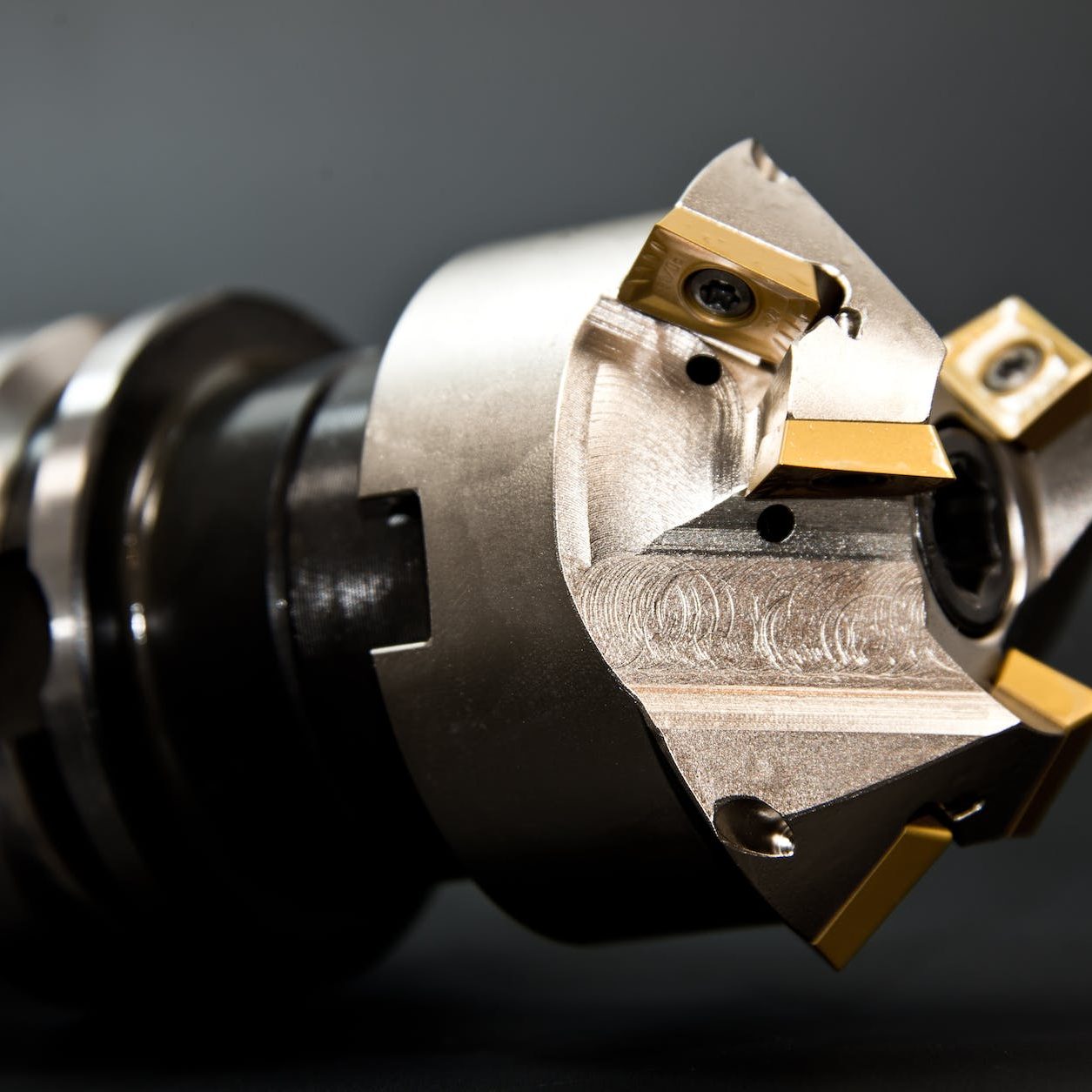

CNC Machining

CNC (Computer Numerical Control) machining involves using computer-controlled machines to precisely shape and cut metal components from raw materials. This service offers high precision, efficiency, and the ability to create complex geometries. Here’s an overview of how CNC machining as a service typically works within a steel fabrication company:

- Project Consultation and Design: The process begins with a consultation between the client and the steel fabrication company. The client discusses their project requirements, design specifications, and the metal components they need. The fabrication company’s engineers might offer design suggestions and insights to optimize the manufacturing process.

- Material Selection: The type of metal used affects the machining process. The fabrication company assists the client in selecting the appropriate steel grade based on factors such as strength, hardness, corrosion resistance, and the intended application of the component.

- CAD Modeling and Programming: Once the design is finalized, the fabrication company’s engineers use CAD software to create detailed 3D models of the components. These models serve as the basis for CNC programming. The CNC machines are programmed with precise instructions for toolpaths, cutting depths, speeds, and feeds.

- CNC Machining: CNC machining involves using computer-controlled machines equipped with various cutting tools to remove material from the raw metal stock. The CNC machines can perform operations like milling, turning, drilling, and threading. These machines are highly accurate and capable of creating complex shapes with tight tolerances.

- Tool Selection and Setup: The fabrication company selects appropriate cutting tools based on the material and the specific machining operations required. Tool setup involves installing and aligning the tools in the CNC machine’s tool holder.

- Machining Process: The CNC machine executes the programmed instructions, precisely cutting and shaping the metal components according to the design. The process is automated and controlled by the CNC software, minimizing human error and ensuring consistent results.

- Quality Control: After machining, the fabricated components undergo quality control checks. Measurements, inspections, and tests are performed to verify that the dimensions, surface finish, and other specifications meet the required standards.

- Secondary Operations: Depending on the project, the fabricated components might require additional processes such as deburring (removing sharp edges), surface finishing (polishing or coating), or assembly with other parts.

- Finishing and Coating: The machined components may undergo finishing processes to improve their appearance, enhance corrosion resistance, or meet specific functional requirements. This can include treatments like painting, powder coating, or plating.

- Delivery and Assembly: Once the CNC machining process is complete, the fabricated components are delivered to the client. The steel fabrication company might also offer assembly services, ensuring that the machined parts are integrated into the final product.

- Customization and Expertise: CNC machining allows for high customization, making it suitable for producing both simple and complex metal components. The fabrication company’s expertise in CNC programming, tool selection, and process optimization is crucial for achieving efficient and accurate results.

- Efficiency and Precision: CNC machining offers high precision and repeatability, making it ideal for creating intricate components with consistent quality. The automation and computer control reduce the risk of errors and increase efficiency.

- Safety and Compliance: Safety protocols are important when operating CNC machines due to their moving parts and potential hazards. The steel fabrication company must ensure the safety of their operators and adhere to industry standards.

We provide clients with the capability to create precise, complex, and functional metal components for a wide range of applications, from industrial machinery to consumer products.